What is pitch polishing?

Pitch polishing is a similar concept to the lapping process except it is using a pitch plate and much finer polishing media.

Lapmaster manufactures and uses single-sided polishing machines for a variety of optical components, i.e. optical flats, filters, prisms and for the refurbishing of customer’s optical components.

Typically, components range in size from 20mm diameter to 600mm diameter. Other sizes are achievable depending on both machine and component size and type.

Significant skill is required for pitch polishing, achieving tighter tolerances for surface flatness, roughness, parallelism and cosmetics than you would achieve using the conventional lapping process with coarser abrasives.

The pitch polishing process also produces a significantly improved surface quality with a typical Ra of less than 5 Å.

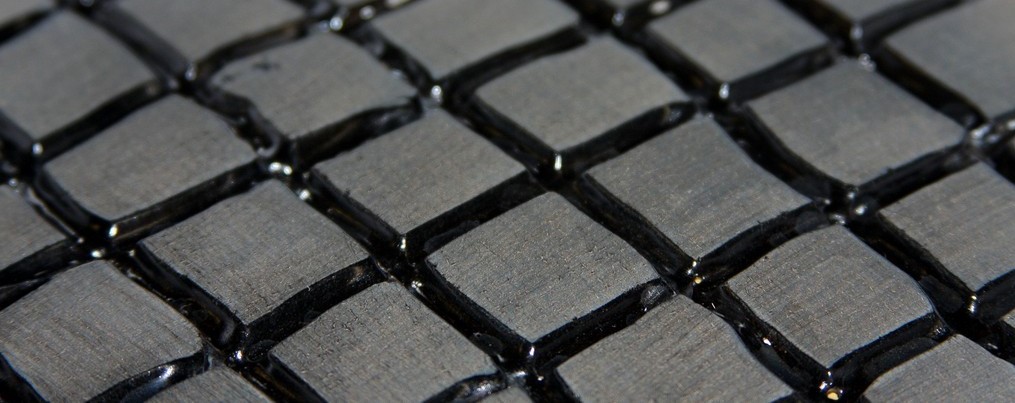

Pitch plates are a semi-fluid surface with a consistency similar to bitumen (asphalt) and are manufactured at our UK site. Concentric, spiral, radial and cross-hatched grooving is either hand cut or machine cut to allow the polishing slurry to flow beneath components, resulting in exceptional surface roughness and surface flatness.

The highly-experienced optical technicians at Lapmaster have extensive knowledge and experience of the optical polishing process and can provide consistent, high quality components.

Typical Optical Polishing Manufacturing Limits on our Lapmaster 48 Air Bearing Machine:

| Specifications | Measurements |

| Diameter | ≤ 300mm Optical Reference Flat |

| Flatness | ʎ/20 |

| Surface Roughness | ≥ 5 Å rms |

| Cosmetics (scratch/dig) | 60-40 to 10-5 |

PRECISION SURFACING SOLUTIONS

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.

Visit SiteLapmaster Wolters

Founded in Chicago in 1948 as a manufacture of lapping and polishing machines for the mechanical seal market, Lapmaster has grown to a worldwide solution provider for more than 20 industries like precision optics and advanced materials.

Visit SiteELB-Schliff

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".

Visit Siteaba Grinding

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.

Visit SiteREFORM

REFORM Grinding Technology GmbH is specialized in the sales, development & production of grinding machines for various applications at its location in Aschaffenburg (Germany).

Visit SiteKEHREN

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.

Visit SiteMicron

Produced in Germany since 2009, MICRON machines are compact and dynamically rigid grinding machines especially designed for Creep Feed and Profile grinding. MICRON is an industry leader in grinding of Hydraulic components like stators, rotors and van pumps.

Visit SitePeter Wolters

Founded in Germany in 1804 by Mr. Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936. In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and special materials of Meyer Burger. Further Information can be found at www.precision-surface.ch

Visit Site