PSS Capital

Manufacturers are always facing major challenges in an increasingly globalized economy: Precision Surfacing Solutions provides a tightly integrated global network of engineering and production facilities. This allows us to offer customer service and support at the highest levels. At PSS, we do everything we can to make it easy for our customers to succeed, and now with our financing arm, PSS Capital, we can put together the right solution for your business needs through one of the many financing solutions available.

Financing Solutions

Stay ahead of the competition and take advantage of every opportunity. PSS Capital provides flexible, competitive financing solutions tailored to meet your specific needs. PSS Capital will put together the right solution for your business needs through one of the many financing solutions available Options include:

- No Money Down

- Deferred Payments

- Step Payments

- Sale Leaseback

- Equipment Trade-In

- Various Term Lengths

Conserve Cash

Paying cash for a long-lived piece of equipment where benefits are derived over time may not be the best use of your available cash.

PSS Capital offers financing options to help you match your expense with the revenue generated from your new PSS equipment.

Preserve Your Credit

Save your credit line for other working capital needs. Let PSS Capital handle the financing of your new equipment.

Benefits of PSS Capital financing

- Acquire new state of the art technology while preserving capital

- Avoid technology obsolescence

- Predictable monthly payments

- Potential accounting and tax benefits

- Option to schedule planned upgrades

- Accelerate ROI

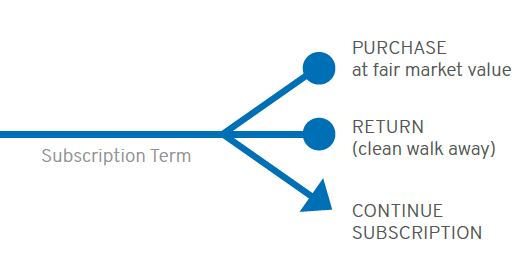

Subscription Program

Our subscription program offers many benefits that are not typically available with traditional financing options, freeing up cash flow and allowing your business to expand quickly and efficiently.

Why Subscription:

Turn Capital Into A Fixed Operating Expense• No Capital Budget Required • Align Expenses with Revenue • Keep Up with New Capabilities • Avoid Equipment Obsolescence |

|

Includes PSS Care Package• Provides lowest cost per piece • Increases efficiency of your machine • A well-maintained machine improves your ability to compete

|

End Of Subscription Options• Return Machine • Upgrade to Latest Model • Extend Subscription for Uninterrupted Productivity • Purchase for Fair Market Value |

Guaranteed AccuracyPSS guarantees the positioning accuracy of all new machines for the full duration of subscription term.

|

Sale & Leaseback

Many businesses are electing to strategically leverage equity in current assets to procure capital for growth and restructuring initiatives.

- Transition Assets into Cash: Quickly transition assets to cash in preparation for swift strategy pivots and growth initiatives.

- Historically Low Rates: Consider the financial benefits of using fixed rate financing at historically low rates.

- No Covenants or Fees: Transactions with PSS Capital never include fees. Our process is completely digital with a focus on simplicity and transparency.

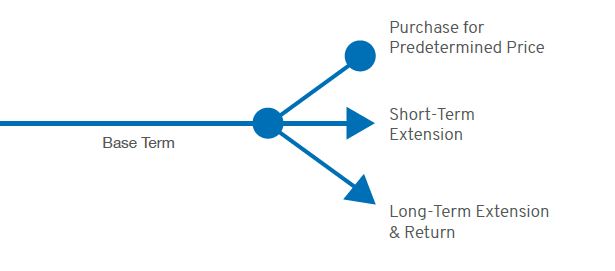

How does it work?

Receive a 100% reimbursement for PSS equipment purchases made in the last 2 years. Then, roll into low, fixed monthly payments as you continue to use your assets, uninterrupted, with the freedom to set up your operating or capital lease with purchase, return, and/or

continued rental end-of-term options.

Requirments:

• Reimbursement for purchases over $100K

• Program available to those signing up for the 3-year PSS Care Package. Care Package gives the lowest cost per piece, increases your overall efficiency and improves your ability to compete due to a well maintained machine.

Equipment Trade-In

The decision of whether or not to upgrade your technology can be a tough one. You don’t want to throw away equipment that still works, but up-to-date technology would help your business become more efficient and grow.

Let PSS Capital unlock the equity in your PSS assets and turn them into cash for your new equipment purchase. This service is provided to you at no additional cost.

PSS Care Packages

Program available to those signing up for the 3-year PSS Care Package with your new equipment purchase. The Care Package provides the lowest cost per piece, increases the overall efficiency of your machine, and improves competitiveness through a wellmaintained machine.

How it works:

- Provide us with a list of previously purchased PSS equipment.

- PSS Capital sells it.

- Proceeds are applied to your next PSS equipment purchase when financed through PSS Capital.

Care Package includes:

• 3 years of support, preventive maintenance, and warranty

• 6-month package of wear and consumable items

Benefits of Financing

• No large, up-front cash outlays

• Align expenses with revenue to accelerate ROI

• Lock in low, fixed rates

• Customize your payment terms

PRECISION SURFACING SOLUTIONS

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.

Visit SiteLapmaster Wolters

Founded in Chicago in 1948 as a manufacture of lapping and polishing machines for the mechanical seal market, Lapmaster has grown to a worldwide solution provider for more than 20 industries like precision optics and advanced materials.

Visit SiteISOG

Since May 2020, the brand ISOG belongs to the globally active Precision Surfacing Solutions Group. With the addition of ISOG to the already existing strong brands within the Group, PSS further strengthens its position as a leading supplier of high quality, best in class technologies in the market of surface quality enhancement solutions.

Visit SiteELB-Schliff

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".

Visit Siteaba Grinding

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.

Visit SiteREFORM

REFORM Grinding Technology GmbH is specialized in the sales, development & production of grinding machines for various applications at its location in Aschaffenburg (Germany).

Visit SiteKEHREN

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.

Visit SiteMicron

Produced in Germany since 2009, MICRON machines are compact and dynamically rigid grinding machines especially designed for Creep Feed and Profile grinding. MICRON is an industry leader in grinding of Hydraulic components like stators, rotors and van pumps.

Visit SitePeter Wolters

Founded in Germany in 1804 by Mr. Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936. In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and special materials of Meyer Burger. Further Information can be found at www.precision-surface.ch

Visit Site